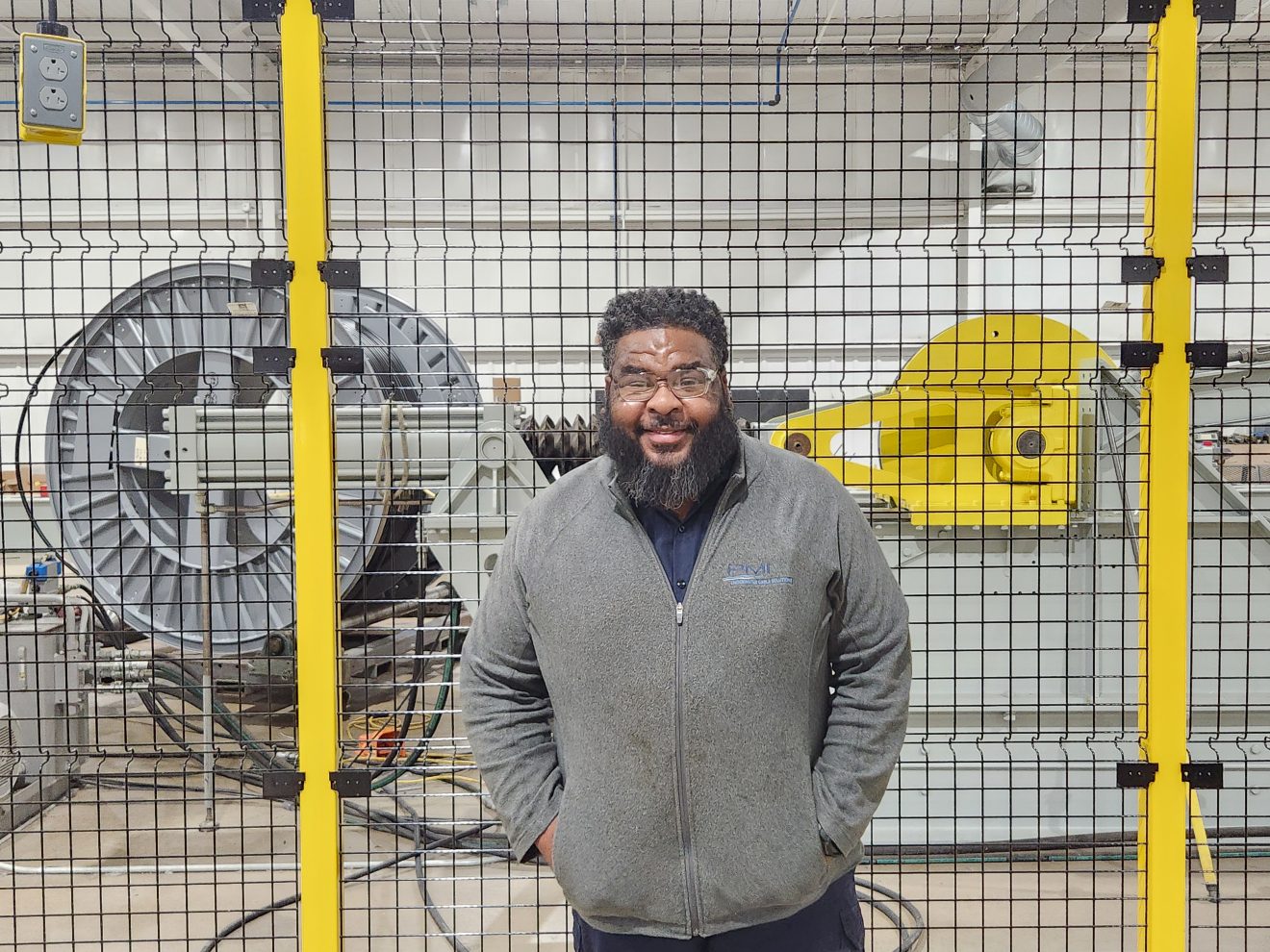

When LaVaughn Chatman, PMI’s production supervisor, graduated from high school, he followed his uncle’s lead and went to work for the same company, General Electric Lighting. He met many people there, including someone who later joined PMI Industries. This person told LaVaughn about a job opening at PMI, which led to LaVaughn being hired by PMI in 2016.

LaVaughn found that he liked being part of a small company, especially the challenges he encountered each day.

“You must come to PMI with your ‘A’ game,” he said. “We design and build underwater marine cable connectors and subsea cable terminations here, it can get involved. Paying attention to details is my number one priority.”

We asked LaVaughn to share more about himself and the work he does at PMI.

Please tell us about the department you work in at PMI Industries.

I was hired to work in Production as a technician I. Later, I became a technician II before spending one year working as a quality control inspector. Eighteen months ago, I moved into the production supervisor position.

What do you enjoy most about the work you do?

I like the fact that I am a true technician here, it is not assembly line work. At PMI, I do the job—from beginning to end—and the responsibility for the work is all mine. I like having direct control.

Depending on the type of cable assembly, we might find ourselves working with thousands of feet of cable, configured in multiple layers, where we need to build terminations for both ends. Some of our work is incredibly involved, especially cable assemblies that contain an inside fiber optic core. Before working alone with fiber optic cables, I went through about a year’s worth of training.

What is an area or a specialty of yours of which you are particularly proud?

I came here with zero experience in fiber optics. Working with these fibers, they are so delicate, it is like an art to be able to manage something that delicate.

How would you describe a “typical” work week?

It starts with an 8 a.m. meeting every day. Then, it is out to the production floor and huddling with the technicians to go over our work and to-do list. Depending on PMI’s deliverables, we may need to shift our focus to help the supply chain manager. We are versatile and wear many hats.

There is always a lot going on here, which makes the work exciting. I always like a good challenge.

When you are not working, what do you enjoy doing?

Being with my family. I am a family man. I have chores to do around the house and kids to raise. One of my kids just graduated from college, and another one is starting his senior year in college. The two youngest are twins, they just started high school.

As Sales Coordinator at PMI Industries, Tijana Milev plays a pivotal role at the heart of customer communication, often serving as the first and last point of contact for clients. With a background in technical industries and multilingual communication, she brings a unique blend of cultural understanding, professionalism, and warmth to every interaction.

“I like to leave people better than I found them,” Tijana says. “It’s much more than a sales transaction. It’s about making a positive impact, going above and beyond, and ensuring our customers feel valued.”

A Collaborative Force Within PMI

Tijana joined PMI in June 2021, drawn by the company’s manufacturing capabilities, collaborative culture, and strong reputation for quality. Her passion for teamwork is clear. “Sales at PMI is deeply connected to every department, from engineering and production to shipping,” she explains. “We’re all aligned to deliver the best possible solution.”

That spirit has made a difference on many projects, including the development of a custom Fiber Optic Splice Kit. “The specifications were ever-changing, and the timeline was tight. It required constant communication and flexibility. It was a true team effort.”

Sales with Purpose: Creating Meaningful Customer ExperiencesFor Tijana, sales is more than closing deals; it’s about creating a thoughtful, white-glove experience, especially with global clients. As PMI expands internationally, her ability to speak multiple languages and connect across cultures is a major asset.

“I was told a long time ago, the more languages you know, the more valuable you are to the world,” she shares. “Growing up multilingual helped me develop an ear for accents and, more importantly, a deep appreciation for other cultures. I make it a point to listen first, communicate intentionally, and build real relationships.”

She adds, “Sometimes it’s as simple as picking up the phone. In our email-heavy world, just calling someone, asking how they’re doing, even what the weather’s like, makes a big impression. It shows effort, care, and humanity.”

Driving Sales & Marketing Impact

Beyond her coordination work, Tijana supports PMI’s Sales & Marketing efforts, helping craft messaging, develop customer materials, and drive outreach across channels. Her insights help shape how PMI presents its solutions to the world.

“I love being involved in both the execution and the story behind what we do,” she says. “It’s not just about answering sales inquiries. It’s about understanding our capabilities, sharing them in a compelling way, and reaching the right people.” Whether behind the scenes or representing PMI at events, Tijana connects the product, the brand, and the people it serves.

Representing PMI on the International Stage

That care and connection shine on the global stage, including at events like the recent EAGE Annual Conference in France and the upcoming IMAGE in Houston, where PMI engages with clients and partners worldwide.

Tijana looks forward to reconnecting with long-time customers, especially from Japan and Norway. “They recognize the quality of our product and the consistency of our service. We’ve built trust over time. These face-to-face moments at events reinforce that trust and show we’re invested in their success.”

Tijana Milev representing PMI Industries at the IMAGE 2024 Conference, connecting with international clients & partners.

Belief in the Product & the People Behind It

Tijana takes pride in PMI’s commitment to quality. “We’re known for the durability and reliability of our products, and I truly believe in what we do. Seeing our test lab in action and the rigor our products go through gives me even more confidence when speaking to clients.”

That belief extends to her colleagues. “Our team is dynamic, talented, and collaborative. We support each other, we innovate together, and we care about the outcomes.”

Growth & Looking Ahead

Since joining PMI, Tijana has contributed to major Sales & Marketing milestones — from refreshing the company’s brand and website to launching new products and improving internal processes. For her, success is about continuous learning, creative problem-solving, and impact.

As PMI grows its global reach, Tijana is excited for what’s ahead. Whether supporting long-time clients or guiding new ones through their first project, she remains focused on what matters most: providing exceptional service, building trusted relationships, and being someone the team can rely on.

“I want to be someone my teammates and our customers can count on,” she says. “That’s what makes the work meaningful.”

Please join us in recognizing Tijana Milev for the important role she plays in helping PMI deliver high-quality, solutions-based service across the globe.

When Hany Koury, PMI Industries Supply Chain Manager, graduated from the American University in Cairo, Egypt, he planned to become a fighter pilot in the U.S Air Force (USAF). A chance meeting changed his plans, however.

He was offered a great opportunity to work with a global aerospace and defense company, which was starting to deploy its F-16 Fighting Falcon fighter aircraft to Egypt. The person who recruited him said they needed someone with Hany’s unique skills, conversant in multiple languages and knowledgeable in computer science, to help manage logistics. Hany accepted the challenge.

For nearly two decades, Hany remained in the Middle East before moving to the U.S. to live near his mom and relatives in northeast Ohio. Hany, who previously had only worked for large, multinational corporations in start-up mode in Egypt, decided to take an inventory control position at a small, family-run business. He liked the atmosphere immediately, especially seeing the direct results of his suggestions and effort.

A few years later, Hany began looking for a new challenge and found a supply chain management opportunity at PMI Industries. He applied and was hired to join PMI’s family-run team.

“I felt how strong family was here,” Hany said. “Bob Eucker and Allan Metzler, who started PMI and worked here until they retired, treated me as part of the family from Day 1.”

Since 2008, Hany has had a front row seat to PMI Industries’ growth as a global leader in engineered protection solutions for underwater marine cable connectors and subsea cable terminations. Now, after 17 years at PMI, Hany plans to retire later this year.

Hany, an avid sailor, has a fresh challenge awaiting him. He and his wife will sail their 40-foot sailboat through the Erie Canal to the Hudson River and along the East Coast. They plan to make Oriental, NC, their home port, visiting family in Ohio periodically.

Have you always worked in the same department and role?

I’ve always worked as a supply chain manager. PMI was very small when I started. We worked mostly with the U.S. Department of Defense. Our DYNA hanger system was just starting up. That is what really launched PMI. After this product was introduced, PMI’s reputation skyrocketed.

What gave you the most satisfaction at work?

Being part of this company and watching it grow, especially internationally. I consider PMI to be one of the top underwater cable solutions providers in the world, thanks in part to our engineers and products.

I worked alongside great engineers like Frank Albert, the PMI engineer who earned several patents and designed several products, including what is known as the EVERFLEX™ BSR Bending Strain Relief product; Bill Green; Konstantin Nakovski, and Jay Marino, P.E., PMI Manager, Engineering, Government Services and Test Lab. They developed amazing products, including the Dyna II® family, a product line that is changeable, adjustable, and reliable. Reliability at sea is a big deal. We have people on ships who specifically ask for our products.

What have your biggest contributions been while here?

My contribution has been to find sources and suppliers. I work closely with our sales, engineering, and operations departments to determine demand requirements, develop action plans to cover supply gaps, and procure manufacturing supplies to be used on the production floor and lab areas.

What are the most significant changes that you have noticed at PMI Industries since you started here?

The way we define ourselves. We’re not a manufacturing company. We are an engineering company that makes solutions. We make a part to solve a customer’s order to their specifications. Plus, we’re able to design, manufacture, and test in a state-of-the-art facility that provides increased production and testing space.

When you were a kid, what did you want to be “when you grow up”?

I wanted to be a fighter pilot in the US Air Force. That opportunity never happened but I was still able to become a recreational pilot and fly gliders with and without motors. One of my favorite hobbies is operating remote-controlled airplanes and sailboats.

Do you have any advice for people just starting at PMI Industries?

Work hard and dream big. This is an amazing company to work for.