EVERFLEX™ BSR Bending Strain Relief

Preserve the Life of Subsea Cables with EVERFLEX Bending Strain Relief (BSR)

The EVERFLEX BSR extends cable life for fixed, towed, and moored systems, and many other oceanographic and offshore petroleum applications.

Features:

- No prep work is required to install and full installation takes minutes with a slip-on design.

- Two models are available: internally threaded sleeve coupling and modified pipe flange mounting ring.

- Both models secure with the appropriate fastening mechanism.

- Light duty models are also available.

By controlling bending stresses and strains at rigid attachment points and limiting bending radius, stress is reduced in the critical transition area with flexible cable interfaces and rigid attachments.

In laboratory tests, double-armored electro-mechanical cables have failed under severe bend conditions in about 5,000 cycles (less than 24 hours of continuous flexing). With an EVERFLEX bending strain relief, under identical loading conditions, the cable life exceeded half a million cycles.

Under high loads and large angle deflections, cable bending is controlled by increasing stiffness of heavier sections of the EVERFLEX bending strain relief near the rigid attachment point.

With an EVERFLEX bending strain relief, the point of maximum bending travels along the length of the cable within the bending strain relief as load conditions vary. This distributes the otherwise localized bending conditions to increase cable life.

Product Description

The EVERFLEX bending strain relief (BSR) is a composite of polyurethane and helical steel rods providing graduated stiffness to limit the bend radius and protect your cable. The EVERFLEX BSR is symmetrical in design and omnidirectional in performance.

Applications

- As a stand-alone BSR, the EVERFLEX can be used on cables and hoses from 19 mm (0.75 in) to 127 mm (5.0 in).

- The EVERFLEX BSR can also be matched fit into our EVERGRIP™, DYNA-GRIP®, and FARMOR™ Termination products

Features and Benefits

- With slip on design and no cable prep work, full installation takes only minutes

- Secures with internally threaded sleeve coupling or flange mounting ring

- With PMI’s EVERFLEX BSR, the point of maximum bending is distributed along the length of the cable inside the BSR as load conditions vary to increase cable life*

- By adjusting design parameters, the stiffness of the EVERFLEX BSR can be tailored to the specific needs of your cable system

*Bend Limiters Improve Cable Performance by Robert L. Swart Oceans 1977

EVERFLEX BSR

In laboratory tests, double armored electro-mechanical cables have failed under severe bend conditions in about 5,000 cycles (less than 2 hours of continuous flexing). With EVERFLEX BSR under identical loading conditions, the cable life exceeded 500,000 cycles.

DEF SERIES (for use with EVERGRIP, DYNA-GRIP, and FARMOR Terminations)

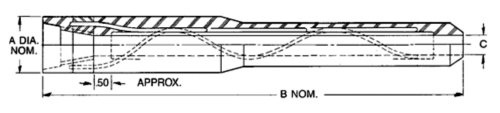

| DASH # | APPROX. CABLE DIA. RANGE | A | B | C |

|---|---|---|---|---|

| 1 | 5.0 mm (0.194") 6.2 mm (0.244") | 29 mm (1.13") | 216 mm (8.50") | 10.4 mm (0.41") |

| 2 | 6.2 mm (0.245") 7.8 mm (0.308") | 35 mm (1.38") | 279 mm (11.00") | 13.2 mm (0.52") |

| 3 | 7.8 mm (0.309") 9.9 mm (0.388") | 48 mm (1.88") | 349 mm (13.75") | 16.5 mm (0.65") |

| 4 | 9.9 mm (0.389") 12.4 mm (0.487") | 54 mm (2.13") | 448 mm (17.62") | 20.6 mm (0.81") |

| 5 | 12.4 mm (0.488") 15.5 mm (0.611") | 67 mm (2.63") | 552 mm (21.75") | 25.4mm (1.00") |

| 6 | 15.5mm (0.612") 19.4 mm (0.765") | 86 mm (3.38") | 679 mm (26.75") | 31.8 mm (1.25") |

| 7 | 19.4 mm (0.766") 24.3 mm (0.957") | 99 mm (3.90") | 981 mm (38.62") | 38.1 mm (1.50") |

| 8 | 24.3 mm (0.958") 30.4 mm (1.197") | 115 mm (4.52") | 1099 mm (43.25") | 47.8 mm (1.88") |

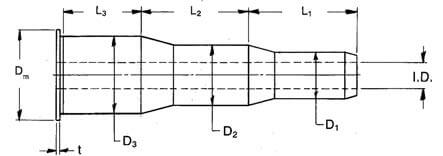

9003547 SERIES (for use on Large Cables & Hose Bundles)

| SIZE | I | II | III | IV | V |

|---|---|---|---|---|---|

| CABLE RANGE | 19.1-28.4 mm (0.75-1.12") | 28.4-44.5 mm (1.12-1.75") | 44.5-63.5 mm (1.75-2.50") | 63.5-88.9 mm (2.50-3.50") | 88.9-127 mm (3.50-5.00") |

| ID | 31.8 mm (1.25") | 50.8 mm (2.00") | 69.9 mm (2.75") | 98.3 mm (3.87") | 136.7 mm (5.38") |

| D3 | 139.7 mm (5.5") | 177.8 mm (7.0") | 228.6 mm (9.0") | 292 mm (11.5") | 356 mm (14.0") |

| D2 | 101.6 mm (4.0") | 139.7 mm (5.5") | 177.8 mm (7.0") | 228.6 mm (9.0") | 292 mm (11.5") |

| D1 | 76.2 mm (3") | 101.6 mm (4.0") | 139.7 mm (5.5") | 177.8 mm (7.0") | 228.6 mm (9.0") |

| L3 | 279 mm (11") | 356 mm (14") | 457 mm (18") | 584 mm (23") | 737 mm (29") |

| L2 | 229 mm (9") | 305 mm (12") | 406 mm (16") | 508 mm (20") | 635 mm (25") |

| L1 | 305-457 mm (12-18") | 406-610 mm (16-24") | 508-762 mm (20-30") | 635-965 mm (25-38") | 838-1270 mm (33-50") |

| DM | 158.2 mm (9") | 196.3 mm (7.73") | 253.5 mm (9.98") | 329.7 mm (12.98") | 393.2 mm (15.48") |

| T | 11.4 mm (0.45") | 12.7 mm (0.50") | 16.0 mm (0.63") | 21.1 mm (0.83") | 25.4 mm (1.00") |

| MIN. BEND RADIUS | 1219 mm (48") | 1626 mm (64") | 1930 mm (76") | 2337 mm (92") | 2870 mm (113") |

| OFF-AXIS LOAD @ 50° (kN-klbf) | 6.7 kN (1.5 klbf) | 13.3 kN (3.0 klbf) | 22.2 kN (5.0 klbf) | 31.1 kN (7.0 klbf) | 40.0 kN (9.0 klbf) |