State-of-the-art facility provides increased production and testing space, improves process flow, and allows for growth of customized cable engineering solutions.

Cleveland, OH, USA, December 15, 2022 – PMI Industries, Inc., a global leader in engineered solutions for underwater marine cable connectors and subsea cable terminations, moves to a new, state-of-the-art facility in January 2023. The move increases production and testing space by more than two-thirds, removes manufacturing constraints, and improves capabilities, resulting in better lead times and inventory control.

“We are excited for the next chapter in PMI’s history with this modernization of our production and office spaces,” said Bob Centa, President. “We are expanding our design, manufacturing, and testing capabilities and expect to dramatically improve our operational efficiencies. The move positions us to grow in the industries we already serve, increase the product and service offerings to our customers, and expand our geographic reach.”

The new facility offers room for a streamlined process flow that will impact many aspects of PMI’s operations, including access to tools and equipment, material handling, and other logistics improvements. Increased space also benefits PMI’s in-house dynamic cable testing and analysis, a value-added step among the capabilities PMI offers. Many at-sea conditions can be simulated by PMI through its testing, which is used to find cable system vulnerabilities or confirm satisfactory performance before the cable is deployed. In-house testing is available as an independent service to third parties, as well as to the industries PMI serves: oil and gas; marine and seismic survey; naval and military; offshore wind, wave, and tidal and sustainable renewable energy; ocean exploration and research; and university and research institutes.

According to Centa, the across-town move will not adversely impact PMI employees, allowing the company to maintain access to its current talent pool and attract new employees to accommodate growth. Additionally, the larger facility, located at 990 Resource Drive, Cleveland, Ohio 44131, U.S.A., offers easy access for delivery and pickup due to its proximity to major highways.

About PMI Industries, Inc.

PMI, celebrating a history of 39 years in 2023, is a global leader in engineered solutions for underwater cable connectors and terminations, including assemblies and hardware. The solutions that PMI designs, manufactures, and tests are used on cable systems for impact and abrasion protection, to prevent bending and provide strain relief, and for dynamic and static cable protection. Its products include high-strength cable terminations and gripping products, towed array and seismic survey lead-in and umbilical terminations, and cable assemblies and hardware. Industries served include: oil and gas; marine and seismic survey; naval and military; offshore wind, wave, and tidal and sustainable renewable energy; ocean exploration and research; and university and research institutes. For additional information, visit www.pmiind.com.

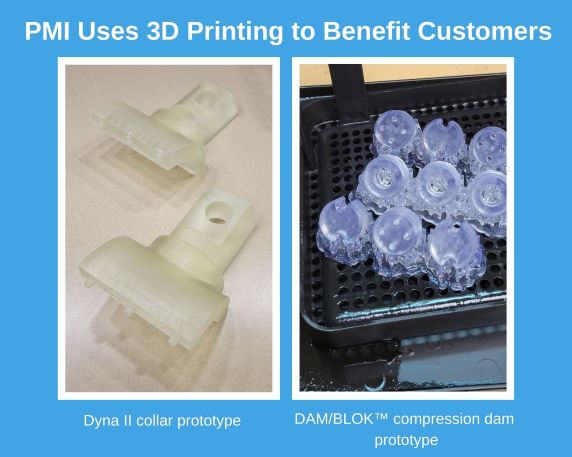

Ongoing improvements in 3D printing are helping PMI explore new ways to provide engineered solutions that meet customer needs. PMI is improving quality control, prototyping crucial components, and experimenting with designs that will reduce assembly time by taking advantage of 3D printing’s additive manufacturing technology.

“The PMI engineering team has used additive manufacturing to make solid three-dimensional objects from a CAD (computer-aided design) file for several years. Because fabrication materials are improving and becoming more cost-effective, we are investigating more ways we can apply the technology,” says Terrence Mathis, PMI Manager, Engineering-Cable Protection.

Engineering team members are managing small projects to improve mold fabrication, potential part casting, compression dam manufacturing, and more.

Analyzing tolerances and variations to improve quality assurance

PMI is using 3D printing to test engineering tolerances of manufactured parts, such as plugs and rings used in a variety of applications. The time needed to measure internal and external features of parts, and ensure their proper fit, can add hours to the quality control process and affect product yields. Also, it can add time-consuming iterations to production if changes occur late in the design cycle.

“Some complex parts have over 20 features that can take four or more hours to inspect,” Mathis says. “Different tools may be needed to measure each section. Depending on the production quantity, it can add a lot of time. Through tolerance optimization, PMI has the potential to improve manufacturing time and reduce cost.”

Prototyping components that customers need to remain operational

PMI is using 3D printing capabilities to prototype crucial components, such as its precision precast compression dams used in DAM/BLOK™ electrical splice kits.

Many of PMI’s field-installable products incorporate helical gripping rods as part of the kit. At times, it is necessary to reterminate a PMI product—sometimes while out on the ocean–to replace helical rods affected by excessive corrosion, or to refurbish the cable connector.

PMI manufactures the DAM/BLOK™ electrical splice kit as a full-ocean depth pressure splice for cable connections. However, there are over 100 existing DAM/BLOK electrical splice kit designs, not including splice kits that can be custom designed for customers. Despite the degree of customization, each kit includes several crucial components, including precision precast compression dams.

Currently, PMI is testing compression dams to ensure it prevents outside seawater as well as leak water within the cable from passing through the splice to the electrical connection. This is especially important at increasing ocean depths.

Developing designs that reduce assembly time

Customers who purchase PMI’s DYNA II cable hangers benefit from its tool-free installation and multiple degrees of freedom, which allow spreader rope loads to pass through with minimal effect on the lead-in and umbilical cables. Like many PMI products, DYNA II can be custom engineered into several configurable kits and accessories.

A collar assembly is just one of the components in a typical DYNA II configuration. PMI is using 3D printing to develop a new standardized collar to be used on legacy and new systems. The prototype collar is 3D printed in a wax resin, which is then cast in stainless steel. The collar serves a build-measure-learn function while saving tooling costs as PMI works to create an improved collar that benefits its customers.

Thinking outside the box to increase development speed

“Our customers turn to us for engineered solutions that include design, fabrication, and testing of subsea tow cables, hardware, assemblies, and protection,” Mathis says. “With a 3D printer, we’re able to take advantage in low-volume situations to revolutionize our development, design and replacement parts in ways that benefit our customers.”

Mr. Centa succeeds Bob Schauer who is retiring after 17 years of service

Cleveland, OH, USA, January 4, 2022 – PMI Industries, Inc., an engineering, manufacturing, and testing company with a global presence servicing energy, both fossil fuel and renewables, marine, research, and government industries announces the appointment of Robert (Bob) J. Centa, MBA to president. Mr. Centa succeeds Bob Schauer who is retiring after 17 years of service to PMI. Mr. Centa was most recently the Chief Financial Officer of The Great Lakes Brewing Co. in Cleveland, Ohio.

“Working at PMI has been truly rewarding and I will miss the daily interactions with the team,” comments Bob Schauer. Mr. Schauer started at PMI with a focus on turning around an underperforming company. As president, he led the company through the oil boom and bust cycles, established an overseas office, all while growing the business during the Covid crisis. “I look forward to spending more time with my family, traveling with my wife, woodworking, volunteering at community organizations, and writing,” comments Mr. Schauer. Speaking on the retirement of Mr. Schauer, PMI Industries board chairman Scott Eucker comments, “The PMI family will miss Mr. Schauer not only from a leadership and inspiration perspective but as a friend. I thank him for all his tireless efforts and wish him joy and happiness in his retirement.”

Mr. Centa brings a broad business acumen and over 25 years of experience in leadership, strategy, operations, and finance in manufacturing and distribution, as well as a wide range of industries and companies as diverse as start-ups, family-owned, private equity, and large publicly traded. Mr. Eucker comments, “I am excited to welcome Bob to the team. His broad business experience and previous leadership roles will be an asset in our company’s growth.” Mr. Centa earned a Master of Business Administration from Cleveland State University and a Bachelor of Business Administration from the University of Cincinnati.

About PMI Industries, Inc.

PMI, celebrating a history of 38 years in 2022, specializes in designing, manufacturing, and testing underwater cable hardware and assemblies. Servicing energy, both fossil fuel and renewables, marine, research, and government industries, PMI builds quality terminations, as well as supplies stoppers and cable grips, umbilical hardware, seismic and cable protection systems. Over many decades we have earned a global reputation for providing the right products at the right time, which ultimately reduces costs by increasing productivity and equipment service life. For additional information, visit www.pmiind.com.