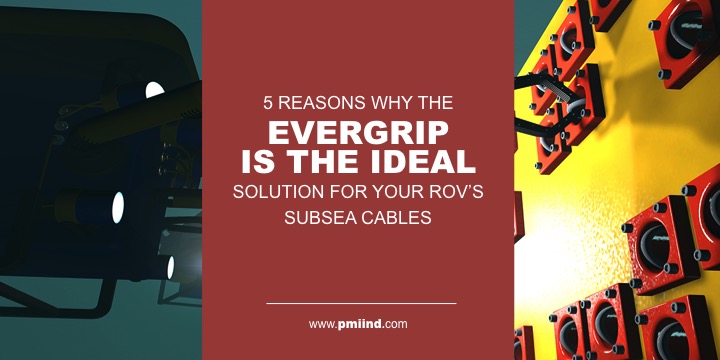

We’ve gone in depth before on how cable terminations are used , now we’re going to explain what sets our terminations apart from the competition.

Many current terminations require an epoxy/polish method of installation. There are many disadvantages to using epoxy. If you’re using heat-cured epoxy, it takes a ½ to cure, but you need an oven to cure it. Room temperature epoxy doesn’t need a special oven, but the cure time can be 2-3 hours or more. When researchers are spending days or weeks out on the ocean gathering information, time is of the essence.

Other terminations on the market don’t use epoxy, but require specialized equipment to install or require extensive cable preparation before installation. In addition, many epoxy-less terminations have a higher connector cost.

PMI provides quality epoxy-less terminations for your ROV needs. Here are 5 that the EVERGRIP Helical Gripping Termination is your ideal solution:

- Faster Installation

The EVERGRIP termination is field installable and easily applied – usually in 30 minutes or less.

- No Special Tools Needed

Our product requires no additional tools or cable preparation to install

- Less Down Time

With the EVERGRIP, there is no need to wait for a termination/retermination to cure.

- Strain Relief for Cables

The special helical rod design relieves strain from the cable. We also have BSR solutions for additional strain relief to prolong cable integrity.

- Reuseable

The housing of EVERGRIP can be used – a Retermination Kit comes at a much lower cost than purchasing a new termination

As new challenges are placed on the ROV industry, PMI continues to provide new solutions to meet those challenges. Whether it’s greater strain capabilities, faster installation or higher cost savings, PMI has the capability to develop and supply the highest quality and reliability solutions.

To read more advice on choosing the best subsea terminations for your project, download our checklist:

7 Questions You Should Be Asking About Your Subsea Terminations

As the energy market continues to turn away from oil and gas and towards renewable energy, many companies that specialize in deep ocean engineering, like PMI, are following suit. One company that has made great efforts to shift from oil and gas into the renewable energy field are the Norwegian subsea specialists Ocean Installer. The company’s advanced vessel, the Normand Vision, was used for work on subsea umbilicals, risers and flowlines (SURF) for major companies in the oil industry. Realizing that their subsea construction support equipment could also be used to work on the underwater cables that connect offshore wind platforms with the power grid, the Normand Vision began working with wind farms, including Germany’s Gode Wind 1 farm. Ocean Installer is not the only subsea construction company to jump on the renewable energy bandwagon. Singapore’s EMAS has also begun adding wind energy projects to their portfolio.

PMI shares the vision of these companies as our energy markets focus on new horizons and is excited to work with customers to solve their cable issues with budget friendly and top quality underwater cable hardware that will maintain cable integrity in every kind of underwater environment.

Read more about Ocean Installer and the Normand Vision.

To find out more about our custom ocean engineered cable hardware equipment, schedule an appointment to talk to our experts today.

As we find our products being used more and more for shipwreck explorations, we were really excited to read about this one nearly in our backyard in Lake Michigan and learning that there are many more to discover.

The bottom of Lake Michigan is literally a graveyard of shipwrecks. Local maritime historians say 1,200 of the 2,000 sunken vessels in Lake Michigan no longer exist because they hit shore and broke apart.

Experts add that about 360 wrecks have been found in the lake’s deeper water, but there are still many wrecks out there that remain undiscovered. Read more…

Subsea equipment (umbilicals, risers, flowlines) and pipelines are generally one third of all expenditure of a total project. Equipment purchases add up quickly and in order to save costs, companies will be looking for hardware with proven results – hardware that increases efficiency and quickly realizes a significant return on investment.

Statoil CEO Eldar Sætre recently stated that over the last ten years, the cost of subsea developments has increased by 250 percent. According to analysts Douglas-Westwood, subsea spending will continue to rise, and there are projects and locations to watch out for. Read more…