Prior to the show, Gordon Drummond was quoted, saying: “In the current low oil price environment, innovation and technology will be more important than ever in driving efficiencies and developing effective solutions to the challenges the industry presently faces, particularly in the North Sea.”

Driving technology in subsea cable applications is what we do. Our cable hardware solutions deliver efficiencies and provide exceptional return on investment.

New technologies, and how their implementation can boost oil and gas exploration, was brought to the forefront at this year’s Subsea Expo.

For the first time, Subsea UK’s annual conference and exhibition, which took place from February 11-13, provided a platform for organizations to introduce, discuss and demonstrate their latest innovations. Read more…

The launch of the Ramform Titan class marine seismic data acquisition ships by Petroleum Geo-Services (PGS) mark a new era of subsea oil and gas exploration. The second of these vessels, the Ramform Atlas was launched in January, 2014. The Ramform Titan and Ramform Atlas are designed and built by PGS to be the most powerful and productive of their kind using the latest marine and electronic seismic technologies.

Every detail of these vessels was evaluated based on optimum productivity and safety including the cable management systems used to deploy and attach up to a 24-streamer array system. The towed streamers consist of several thousand recording sensors over an area greater than 3,000 acres (12 km2), or 3.5 times the size of New York’s Central Park.

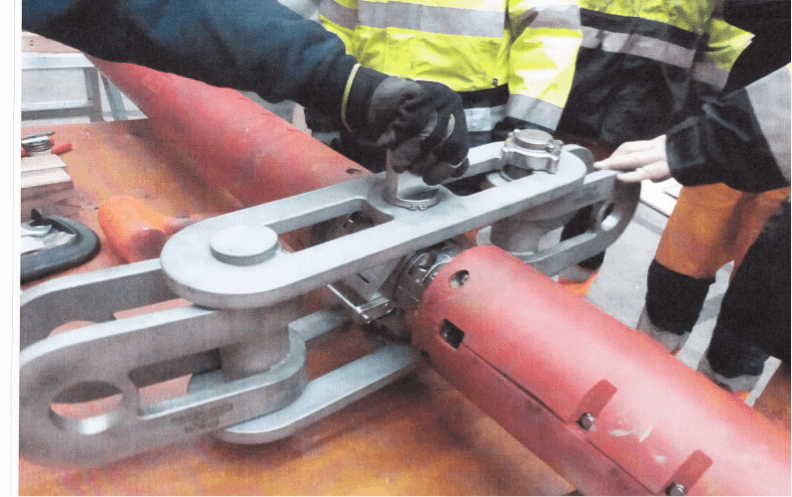

The engineers at PGS have chosen the latest proven technologies available throughout the Ramform Titan-class ships, including the new PMI Dyna-Hanger II and Dyna-BSR cable management systems. These systems provide significantly higher load capacities to accommodate the demands of extreme towing loads caused by wider streamer arrays. As a bonus, the major components of both systems can be installed, or removed, in just minutes without special tools or extensive personnel training to increase on deck productivity and reduce downtime.

The Dyna-Hanger II cable management system uses exclusive patent pending designed symmetrical suspension arms with tool-less features and helical rods. It is designed with a hinged collar that snaps around the housing and is secured with just a quick-release pin. A specially designed housing prevents the attachment point from shifting on the lead-in cable while the collar design enables the cable to rotate freely under tension. It is capable of accommodating loads up to 100% of the cable’s rated breaking strength.

The Dyna-BSR bending strain relief system provides cable bending and abrasion protection, while enabling rotation of various cable attachments. It replaces traditional slip-on bending strain relief systems that use a one-piece body design. Instead, the Dyna-BSR patent pending two-piece system can be installed or removed at any time during deployment or retrieval procedures. It is designed with a reinforced polyurethane, two-part shell to provide added strength and flexibility. A unique fastener system quickly secures the shells together. In total, the system offers graduated stiffness to protect cables from off-axis loads through a wide range of angle combinations by maintaining a safe minimum bend radius.

“Everything on the Ramform Titan class was chosen for its contribution to our primary goals of providing optimal seismic productivity and crew safety,” according to Sverre Olsen, Technical Manager at PGS. “Every sub-system we have, builds on the total system to achieve our goals. PMI systems were chosen because they continue to meet PGS productivity and higher load requirements.”

“The successful PGS installation is a result of our conversations with customers about their challenges then developing cable hardware and support services to meet their needs,” said Bob Schauer, president, PMI industries. “We are focused on unmatched support for our customers. Whether it is easy-to-use hardware, engineering support or comprehensive cable testing services, we listen and then perform.

The launch of the Ramform Titan class marine seismic data acquisition ships by Petroleum Geo-Services (PGS) mark a new era of subsea oil and gas exploration. The second of these vessels, the Ramform Atlas was launched in January, 2014. The Ramform Titan and Ramform Atlas are designed and built by PGS to be the most powerful and productive of their kind using the latest marine and electronic seismic technologies.

Every detail of these vessels was evaluated based on optimum productivity and safety including the cable management systems used to deploy and attach up to a 24-streamer array system. The towed streamers consist of several thousand recording sensors over an area greater than 3,000 acres (12 km2), or 3.5 times the size of New York’s Central Park.

The engineers at PGS have chosen the latest proven technologies available throughout the Ramform Titan-class ships, including the new PMI Dyna-Hanger II and Dyna-BSR cable management systems. These systems provide significantly higher load capacities to accommodate the demands of extreme towing loads caused by wider streamer arrays. As a bonus, the major components of both systems can be installed, or removed, in just minutes without special tools or extensive personnel training to increase on deck productivity and reduce downtime.

The Dyna-Hanger II cable management system uses exclusive patent pending designed symmetrical suspension arms with tool-less features and helical rods. It is designed with a hinged collar that snaps around the housing and is secured with just a quick-release pin. A specially designed housing prevents the attachment point from shifting on the lead-in cable while the collar design enables the cable to rotate freely under tension. It is capable of accommodating loads up to 100% of the cable’s rated breaking strength.

The Dyna-BSR bending strain relief system provides cable bending and abrasion protection, while enabling rotation of various cable attachments. It replaces traditional slip-on bending strain relief systems that use a one-piece body design. Instead, the Dyna-BSR patent pending two-piece system can be installed or removed at any time during deployment or retrieval procedures. It is designed with a reinforced polyurethane, two-part shell to provide added strength and flexibility. A unique fastener system quickly secures the shells together. In total, the system offers graduated stiffness to protect cables from off-axis loads through a wide range of angle combinations by maintaining a safe minimum bend radius.

“Everything on the Ramform Titan class was chosen for its contribution to our primary goals of providing optimal seismic productivity and crew safety,” according to Sverre Olsen, Technical Manager at PGS. “Every sub-system we have, builds on the total system to achieve our goals. PMI systems were chosen because they continue to meet PGS productivity and higher load requirements.”

“The successful PGS installation is a result of our conversations with customers about their challenges then developing cable hardware and support services to meet their needs,” said Bob Schauer, president, PMI industries. “We are focused on unmatched support for our customers. Whether it is easy-to-use hardware, engineering support or comprehensive cable testing services, we listen and then perform.”

The new Ramform Titan and Ramform Atlas put PGS further ahead as the leader in safe, productive and efficient 3D seismic acquisition.

About PGS

Petroleum Geo-Services (PGS) offers a broad range of products including seismic and electromagnetic services, data acquisition, processing, reservoir analysis/interpretation and multi-client library data. We help oil companies find oil and gas reserves offshore worldwide.

PGS was founded in Norway in 1991, with 2 seismic ships and some highly innovative ideas on how to reshape the industry. Today we share the same drive to innovate as inspired our founders, though the team is bigger:

- 14 offshore seismic vessels

- 21 data processing centers

- 35 offices worldwide, employing over 70 nationalities

PGS has a presence in over 25 countries with regional centers in London, Houston and Singapore. Our headquarters is in Oslo, Norway and the PGS share is listed on the Oslo stock exchange (OSE:PGS).

For more information, visit: www.pgs.com

About PMI Industries, Inc.

PMI Industries, Inc. provides underwater cable hardware products and services to customers worldwide including exploration, military, commercial and scientific organizations. The company supports domestic and international customers with comprehensive subsea knowledge, application assistance, custom designs and functional testing to assure performance and reliability in harsh operational environments.

The company was founded to solve cable and wire rope application problems. It introduced unique wire helix design to grip a conductor that provides the strength needed for assured cable connections while ensuring cable integrity.

For more information, visit: www.pmiind.com