Michelle Kane, mechanical engineer at PMI, was born and raised in northeast Ohio. She stayed in the region to attend Cleveland State University, which offered a 4+1 program. That program enabled Michelle to earn a bachelor’s and master’s degree in mechanical engineering in five academic years instead of six.

After college, Michelle worked at a temperature sensor company in Mansfield. Midway through the global pandemic, however, Michelle decided that she preferred employment closer to her family. Michelle’s job search led her to PMI, which she joined in April, 2022.

“I enjoy the variety in my day-to-day work,” she said. “I work in the engineering department and am involved with many different projects and all our departments. The environment is fast-paced and I’m always learning something new.”

We asked Michelle to share more about herself and the work she does at PMI.

What machines and materials have you worked with?

I often work on projects that involve 3D printing and the use of an autoclave. We use the autoclave to replicate ocean depth and for pressure testing.

What is a specialty of yours that you are particularly proud of?

Being organized. I manage multiple projects, as well as PMI’s ISO and safety programs. I use weekly to-do lists to keep track of what needs to be done.

PMI Industries’ Michelle Kane and Terrence Mathis meet Sasquatch, also known as Bigfoot, at the Offshore Technology Conference (OTC). For the PMI team, attending trade shows are one way it fosters and builds customer relationships.

How would you describe a “typical” work week?

A typical work week for me involves working with a variety of departments and people inside and outside of the company. For instance, I provide project information and updates on customer interaction to our sales team. With the production team, the focus is on work orders, procedures, testing, and training. In our quality control, supply chain, and shipping and receiving areas, my involvement ranges from parts to be ordered or evaluated to products shipped to customers or vendors. In my ISO role, I work with all our departments to collect data for key performance indicators, which are used to update and improve procedures and processes and/or create new guidance documents as needed.

What have you learned about the industry? Are there any trends or changes you are following?

I didn’t know just how specialized PMI’s business was when I joined 19 months ago. I have learned so much about vessels, surveys, remote-operated vehicles, fiber optics, etc. and the solutions that PMI designs, manufactures, and tests. At PMI, I’m assisting or leading projects and get to be directly involved with our products, such as our new fiber optic splice kit, Dyna II family, EVERFLEX™ BSR Bending Strain Relief, DAM/BLOK™ Electrical Cable Splice Kit, and other marine cable connectors and subsea cable terminations.

One group I follow on social media is called, “Interesting Engineering.” It has been posting about fiber optics and fiber optic cables and the alternate ways they are being used. One example mentioned using fiber optic cables to track whales using seismographs. Interestingly, PMI’s solutions are assisting in this offshore work and data collection of whale songs!

When you’re not working, what do you enjoy doing?

Northeast Ohio has a huge volleyball community. I am part of this and play volleyball about five days a week. I also enjoy reading novels and manga, watching anime and TV shows, going to concerts, and spending time with friends, family, and my three cats.

When you were a kid, what did you want to be “when you grow up”?

I wanted to do special FX makeup, either for movies or plays. I began studying chemical engineering to “make” makeup. That’s when I discovered how much I despise chemistry! I switched to mechanical engineering after two semesters of general chemistry in my freshman year of college.

By Bob Centa, President of PMI Industries

The start of a new year is a wonderful opportunity to express appreciation, reflect on past accomplishments, and look forward to the future. At PMI Industries, we have many reasons to be proud of the work we are doing and the value and opportunities this creates for our key stakeholders.

Our business provides engineered protection solutions for underwater marine cable connectors and subsea cable terminations, including assemblies and hardware that are used in electrical, optical, pressure, and mechanical applications. The solutions we create enable us to service customers around the world through the four different markets in which we operate. We look forward to building upon the strength of these relationships as we embark on our 40th year in business.

Acknowledging PMI’s relationships

PMI’s key stakeholders include our shareholders, employees, suppliers, and customers. We appreciate our shareholders, who provide support when needed and the autonomy to think and act for the long-term health and growth of the business. We are thankful for our employees, who embody a “can-do” attitude and deserve thanks because of the ways in which they embrace new opportunities presented by our customers and help us meet daily operational challenges. We are indebted to our suppliers for their critical inputs, helping us meet the needs of our customers and/or our own operations.

We are grateful to our customers, many of which have done business with PMI for decades. Whether old or new, our customers can count on our subsea cable engineering experts to design, manufacture, and test cable systems for impact and abrasion protection, to prevent bending and provide strain relief, and for dynamic and static cable protection.

Gaining momentum in 2023

We made improvements and changes in 2023 designed to better serve our customers and position us for growth. Among our biggest accomplishments were:

- Facilities upgrade – PMI relocated to a larger, state-of-the-art facility early in 2023. The new space allows us to better address customers’ needs and requirements through operational efficiencies and improved manufacturing and testing processes. The facility offers added bonuses, which include:

- Activating sustainable manufacturing processes that conserve energy and natural resources, such as LED lighting

- Improving ingress and egress for our customers and suppliers

- Positively impacting employee retention and recruitment

- Our people – Key additions in engineering, quality control, accounting, and production were made to an already dedicated team. Each member of the PMI team is making significant contributions to meet, and exceed, our customers’ expectations. You can meet two of them, Rich Sinkovic and Terrence Mathis, who were featured in recent stories on our website and social media.

- New products – A customer referral brought together our sales, engineering, supply chain, production, and quality control teams to provide a solution to a new challenge. The PMI team did an outstanding job in satisfying the customer and exceeding their requirements. Additionally, this product has the potential to cross over into many other applications. The project was a perfect example of PMI at its finest in terms of how we meet the unique needs of our customers, despite significant challenges.

- Our services – We took the opportunity to better communicate the extensive testing capabilities we offer. With the growth in the diameter of and materials used in cables, we have been reminding customers and interested cable manufacturers about PMI’s in-house dynamic cable testing and analysis. It provides an extra confidence boost with their cable system components and the integrity of the complete system.

- New markets – We successfully completed production of a new renewable energy product and collaborated with the customer during installation. As the world seeks alternatives to meet global energy needs, PMI is excited about the growth prospects this market offers.

- Improved communications – Significant enhancements made to our website and social medial channels have made them more informative and user friendly. We are regularly updating our LinkedIn and X (formerly Twitter) accounts with interesting content and encourage you to check it out.

Building new opportunities in 2024

We are excited about what 2024 holds. We enter the year leveraging our solid foundation, which allows us to better meet the needs of our customers and deliver existing products while creating new ones in the markets we serve.

Two key areas on which PMI is focused in 2024 are:

- Customer and supplier engagement – While we realize the world has changed due to the global pandemic, we feel strongly about the importance of relationships. We remain committed to meeting customers and suppliers whenever possible, whether at trade shows, their place of business, or anywhere else in the world.

- Processes – With the core infrastructure firmly in place, our last big initiative is the replacement of our Enterprise Resource Planning (ERP) systems. Replacing our ERP system is not just an update; it’s a strategic move towards future-proofing our business operations, enhancing efficiency, and maintaining our competitive edge in the market.

We would love to hear from you. Please contact us if you have any questions or if there is anything we can do for you.

Terrence Mathis, PMI Mechanical Engineer II, began working for PMI Industries as a part-time project engineer during his last semester at Case Western Reserve University. Terrence was pursuing a mechanical engineering degree and a minor in design and manufacturing. In January, 2017, Terrence joined PMI full time.

Over the years, Terrence has grown and expanded his mechanical engineering expertise within PMI’s team-oriented setting.

“Being part of a small company has allowed me to make an impact in multiple areas, such as sales, production, quality control, and engineering,” he said.

Many PMI customers know of and/or have met Terrence through the engineered protection solutions that he helps develop for customers. We asked Terrence to share more about himself.

What departments have you worked in?

I have always been in the engineering department. I have also helped to support the ISO and quality control (QC) programs periodically.

What machines and materials have you worked with?

Most of my work is done on a computer using CAD (computer-aided design). The program is utilized to help create prototypes and parts used in marine environments. They also help us plan underwater marine cable connector and subsea cable termination projects, store and manipulate data, present information, and more.

I’m proficient in CMM (coordinate measuring machine) programming, which is an important tool used to measure parts for quality control. It’s also been useful in the ways we’re taking advantage of 3D printing’s additive manufacturing technology.

What do you enjoy most about the work you do?

I like being part of a dynamic, involved workplace. We’re a smaller organization, which allows me to build relationships across all departments and feel ‘visible’ in the workplace.

What is a specialty of yours that you are particularly proud of?

I am proud of my CAD skills, which I’ve continued to hone since learning it in college and now use to solve customer problems. The cool part about CAD is that there is always more to learn and many ways to challenge yourself to become more proficient.

At an Offshore Technology Conference, Terrence Mathis, Mechanical Engineer II at PMI Industries, shared his experiences and recommendations as a young professional attending the conference.

At an Offshore Technology Conference, Terrence Mathis, Mechanical Engineer II at PMI Industries, shared his experiences and recommendations as a young professional attending the conference.

How would you describe a “typical” work week?

My work week evolves constantly, depending on many factors, such as customer inquiries, questions about product applications, and the larger, custom projects I oversee. I also support our quality control department with part inspections.

What have you learned about the industry? Are there any trends or changes you are following?

This industry is what we call a niche of a niche. It is expanding quickly, and it is our job to stay up to date with changes so that we can provide high-quality products to our customers. The marine energy industry is expanding and we’re positioning our company to take advantage of this.

I also personally follow the renewable energy sector, especially as it grows in the U.S. A project of interest to me is the Icebreaker Wind Project, which has the potential to become the first freshwater offshore wind farm in Ohio and the U.S.

I am committed to networking. I am a member of National Society of Black Engineers (NSBE), which I originally joined while in college.

When you were a kid, what did you want to be “when you grow up”?

I’ve known that I wanted to be a mechanical engineer since I was 10 years old. I didn’t know what industry I would work in, but the idea of being an engineer has always fascinated me.

When you’re not working, what do you enjoy doing?

I have lived in Cleveland, Ohio, my entire life. My parents and older siblings live here, too. I follow all the Cleveland sports teams and am a big fan of the Cavs and Browns, as well as any team that Lebron James plays for.

Outside of work, I spend a lot of time participating in fitness activities, such as playing basketball with friends or going on runs throughout the city to build up my endurance and stay in shape.

I am also an avid fragrance collector with a large collection of fragrances that I have obtained over the years. Travel, whether by car or flying, is another interest of mine and I am always searching for fund-friendly trips.

Rich Sinkovic, sales engineer at PMI Industries, joined PMI on December 15, 2021. Previously, he had been a sales engineer with a company that produced automotive manufacturing equipment.

In the short time he has been with the company, Rich has gained a lot of knowledge about PMI’s engineered protection solutions for underwater marine cables and subsea cable terminations, including assemblies and hardware that are used in electrical, optical, pressure, and mechanical applications. He has taken what he’s learned about PMI’s underwater marine cable connectors and subsea cable terminations and used it to ensure successful projects for PMI’s customers.

As one of PMI’s newer team members, we asked Rich to share a little about himself.

Please tell us about your education and career path on your way to PMI Industries.

I earned an electrical engineering degree and mathematics minor from Ohio University. For the last 14 years, I have worked as a sales engineer.

What do you enjoy most about the work you do?

Customer interactions are the best part of my work. As I learn about our customers’ projects, I’m able to explain the benefits of our products or services and take their feedback to our engineers and production team.

What is a specialty of yours that you are particularly proud of?

I pride myself on my attention to detail. This helps greatly as I look at costs, lead times, and engineering drawings daily.

How would you describe a “typical” work week?

Typically, I’m working at PMI’s new, state-of-the-art facility, which we moved into in January, 2023. My day is spent communicating with customers via email, phone, and video calls, attending internal meetings to collaborate on new inquiries and new PMI products, and/or researching new markets and opportunities. Often, I visit our lab/production areas to see the progress of production and testing. Occasionally, I travel to visit customers and attend tradeshows and conferences.

Rich Sinkovic at the Lockheed Martin Rotary & Mission Systems Supplier Conference. PMI is one of Lockheed’s suppliers.

What have you learned about the industry? Are there any trends or changes you are following?

Every project is slightly different, allowing me to continually learn. For instance, one of the markets we work in is seismic and marine surveys. To properly survey, the air guns and streamers need to maintain a certain distance apart from each other. This is accomplished with our Dyna II suspension system.

A recent trend we’ve seen is the move from traditional streamer surveys to node surveys. This reduces the number of streamers needed because the nodes capture the data. We have had many conversations with our customers and designed new Dyna II systems that can handle the larger cables used on node surveys. We plan to follow this closely with our customers and will create new systems as the market requires.

Rich Sinkovic and a friend enjoy live music at City Stages, a summer concert series hosted by the Cleveland Museum of Art at Transformer Station, its satellite location in downtown Cleveland, Ohio.

When you’re not working, what do you enjoy doing?

I live in Lakewood, Ohio, a suburb of Cleveland. I grew up in northeast Ohio and am a Cleveland Browns fan. I like to spend time with family and friends pursuing my interests. For instance, I like to attend live music, go to movies, and search for vinyl records or find new plants to add to my collection. If I’m hanging out at home, I like to read comics and graphic novels, watch TV, or build Lego sets.

When you were a kid, what did you want to be “when you grow up”?

I wanted to work in movies. Not necessarily as an actor, but to be involved in the industry in some capacity.

In case you missed it, we’ve moved–and the PMI team is settled into our new home!

Housed at our previous facility since PMI’s inception in 1984, it was time for an upgrade. We’re now located at 990 Resource Drive, Cleveland, Ohio 44131, U.S.A., just 7 miles away from the old facility.

The new state-of-the-art facility provides increased production and testing space, improves process flow, and allows for the growth of customized cable engineering solutions.

“By moving to the new facility, we’re able to better meet the needs and requirements of our customers,” said Bob Centa, President. “For instance, our production flow is better suited to meet the trends in the industries we serve, improving productivity and efficiency in handing large cable reels.”

Other benefits of the new facility include:

- Expansion of PMI’s design, manufacturing, and testing capabilities that will dramatically improve operational efficiencies.

- Increase product and service offerings to PMI’s customers.

- Expand PMI’s geographic reach.

We’re excited about this new chapter and we’d love to share a bit of the transition to our new space with you through the pictures below.

We are proud to announce that after an external audit, the Quality Management System of PMI Industries, Inc. has been assessed and approved by Smithers Quality Assessments, Inc., to the following quality management system standard and requirements: ISO 9001:2015.

This certifies that our Quality Management System is applicable to design, manufacture and distribute offshore, subsea cable hardware assemblies, and provide testing services. Which demonstrates our commitment to our Quality Policy Statement:

PMI Industries, Inc. provides offshore, subsea cable hardware and assemblies that increase efficiency, reduce failures, and improve installation and deployment time. We are committed to meeting customer expectations, and all applicable requirements, through continuous improvement of our processes. Our advantage is delivering quality, on-time and cost-effective products and services.

Since 2017, PMI has partnered with Smithers Quality Assessments, an accredited quality and environmental management systems certification body, to achieve certification.

“This certification reflects our longstanding commitment to quality, continuous improvement, and our customers,” said Bob Centa, President of PMI Industries, Inc. “It demonstrates the significant effort by the PMI team to continue to uphold the ISO standard throughout the company.”

PMI, celebrating a history of 39 years in 2023, is a global leader in engineered solutions for underwater marine cable connectors and terminations, including assemblies and hardware. The solutions that PMI designs, manufactures, and tests are used on cable systems for impact and abrasion protection, to prevent bending and provide strain relief, and for dynamic and static cable protection.

Our products include high-strength cable terminations and gripping products, towed array and seismic survey lead-in and umbilical terminations, and suspension cable assemblies and hardware.

Our engineered subsea cable hardware assemblies are designed for the following:

- US Navy & Defense Contractors

- Oil & Gas

- Marine & Seismic Survey

- Ocean Exploration & Research

- Offshore Wind, Wave, and Tidal

- University and Research Institutes

State-of-the-art facility provides increased production and testing space, improves process flow, and allows for growth of customized cable engineering solutions.

Cleveland, OH, USA, December 15, 2022 – PMI Industries, Inc., a global leader in engineered solutions for underwater marine cable connectors and subsea cable terminations, moves to a new, state-of-the-art facility in January 2023. The move increases production and testing space by more than two-thirds, removes manufacturing constraints, and improves capabilities, resulting in better lead times and inventory control.

“We are excited for the next chapter in PMI’s history with this modernization of our production and office spaces,” said Bob Centa, President. “We are expanding our design, manufacturing, and testing capabilities and expect to dramatically improve our operational efficiencies. The move positions us to grow in the industries we already serve, increase the product and service offerings to our customers, and expand our geographic reach.”

The new facility offers room for a streamlined process flow that will impact many aspects of PMI’s operations, including access to tools and equipment, material handling, and other logistics improvements. Increased space also benefits PMI’s in-house dynamic cable testing and analysis, a value-added step among the capabilities PMI offers. Many at-sea conditions can be simulated by PMI through its testing, which is used to find cable system vulnerabilities or confirm satisfactory performance before the cable is deployed. In-house testing is available as an independent service to third parties, as well as to the industries PMI serves: oil and gas; marine and seismic survey; naval and military; offshore wind, wave, and tidal and sustainable renewable energy; ocean exploration and research; and university and research institutes.

According to Centa, the across-town move will not adversely impact PMI employees, allowing the company to maintain access to its current talent pool and attract new employees to accommodate growth. Additionally, the larger facility, located at 990 Resource Drive, Cleveland, Ohio 44131, U.S.A., offers easy access for delivery and pickup due to its proximity to major highways.

About PMI Industries, Inc.

PMI, celebrating a history of 39 years in 2023, is a global leader in engineered solutions for underwater cable connectors and terminations, including assemblies and hardware. The solutions that PMI designs, manufactures, and tests are used on cable systems for impact and abrasion protection, to prevent bending and provide strain relief, and for dynamic and static cable protection. Its products include high-strength cable terminations and gripping products, towed array and seismic survey lead-in and umbilical terminations, and cable assemblies and hardware. Industries served include: oil and gas; marine and seismic survey; naval and military; offshore wind, wave, and tidal and sustainable renewable energy; ocean exploration and research; and university and research institutes. For additional information, visit www.pmiind.com.

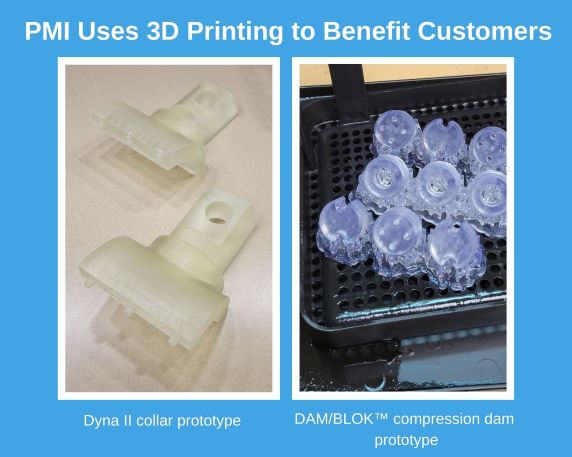

Ongoing improvements in 3D printing are helping PMI explore new ways to provide engineered solutions that meet customer needs. PMI is improving quality control, prototyping crucial components, and experimenting with designs that will reduce assembly time by taking advantage of 3D printing’s additive manufacturing technology.

“The PMI engineering team has used additive manufacturing to make solid three-dimensional objects from a CAD (computer-aided design) file for several years. Because fabrication materials are improving and becoming more cost-effective, we are investigating more ways we can apply the technology,” says Terrence Mathis, PMI Manager, Engineering-Cable Protection.

Engineering team members are managing small projects to improve mold fabrication, potential part casting, compression dam manufacturing, and more.

Analyzing tolerances and variations to improve quality assurance

PMI is using 3D printing to test engineering tolerances of manufactured parts, such as plugs and rings used in a variety of applications. The time needed to measure internal and external features of parts, and ensure their proper fit, can add hours to the quality control process and affect product yields. Also, it can add time-consuming iterations to production if changes occur late in the design cycle.

“Some complex parts have over 20 features that can take four or more hours to inspect,” Mathis says. “Different tools may be needed to measure each section. Depending on the production quantity, it can add a lot of time. Through tolerance optimization, PMI has the potential to improve manufacturing time and reduce cost.”

Prototyping components that customers need to remain operational

PMI is using 3D printing capabilities to prototype crucial components, such as its precision precast compression dams used in DAM/BLOK™ electrical splice kits.

Many of PMI’s field-installable products incorporate helical gripping rods as part of the kit. At times, it is necessary to reterminate a PMI product—sometimes while out on the ocean–to replace helical rods affected by excessive corrosion, or to refurbish the cable connector.

PMI manufactures the DAM/BLOK™ electrical splice kit as a full-ocean depth pressure splice for cable connections. However, there are over 100 existing DAM/BLOK electrical splice kit designs, not including splice kits that can be custom designed for customers. Despite the degree of customization, each kit includes several crucial components, including precision precast compression dams.

Currently, PMI is testing compression dams to ensure it prevents outside seawater as well as leak water within the cable from passing through the splice to the electrical connection. This is especially important at increasing ocean depths.

Developing designs that reduce assembly time

Customers who purchase PMI’s DYNA II cable hangers benefit from its tool-free installation and multiple degrees of freedom, which allow spreader rope loads to pass through with minimal effect on the lead-in and umbilical cables. Like many PMI products, DYNA II can be custom engineered into several configurable kits and accessories.

A collar assembly is just one of the components in a typical DYNA II configuration. PMI is using 3D printing to develop a new standardized collar to be used on legacy and new systems. The prototype collar is 3D printed in a wax resin, which is then cast in stainless steel. The collar serves a build-measure-learn function while saving tooling costs as PMI works to create an improved collar that benefits its customers.

Thinking outside the box to increase development speed

“Our customers turn to us for engineered solutions that include design, fabrication, and testing of subsea tow cables, hardware, assemblies, and protection,” Mathis says. “With a 3D printer, we’re able to take advantage in low-volume situations to revolutionize our development, design and replacement parts in ways that benefit our customers.”

Mr. Centa succeeds Bob Schauer who is retiring after 17 years of service

Cleveland, OH, USA, January 4, 2022 – PMI Industries, Inc., an engineering, manufacturing, and testing company with a global presence servicing energy, both fossil fuel and renewables, marine, research, and government industries announces the appointment of Robert (Bob) J. Centa, MBA to president. Mr. Centa succeeds Bob Schauer who is retiring after 17 years of service to PMI. Mr. Centa was most recently the Chief Financial Officer of The Great Lakes Brewing Co. in Cleveland, Ohio.

“Working at PMI has been truly rewarding and I will miss the daily interactions with the team,” comments Bob Schauer. Mr. Schauer started at PMI with a focus on turning around an underperforming company. As president, he led the company through the oil boom and bust cycles, established an overseas office, all while growing the business during the Covid crisis. “I look forward to spending more time with my family, traveling with my wife, woodworking, volunteering at community organizations, and writing,” comments Mr. Schauer. Speaking on the retirement of Mr. Schauer, PMI Industries board chairman Scott Eucker comments, “The PMI family will miss Mr. Schauer not only from a leadership and inspiration perspective but as a friend. I thank him for all his tireless efforts and wish him joy and happiness in his retirement.”

Mr. Centa brings a broad business acumen and over 25 years of experience in leadership, strategy, operations, and finance in manufacturing and distribution, as well as a wide range of industries and companies as diverse as start-ups, family-owned, private equity, and large publicly traded. Mr. Eucker comments, “I am excited to welcome Bob to the team. His broad business experience and previous leadership roles will be an asset in our company’s growth.” Mr. Centa earned a Master of Business Administration from Cleveland State University and a Bachelor of Business Administration from the University of Cincinnati.

About PMI Industries, Inc.

PMI, celebrating a history of 38 years in 2022, specializes in designing, manufacturing, and testing underwater cable hardware and assemblies. Servicing energy, both fossil fuel and renewables, marine, research, and government industries, PMI builds quality terminations, as well as supplies stoppers and cable grips, umbilical hardware, seismic and cable protection systems. Over many decades we have earned a global reputation for providing the right products at the right time, which ultimately reduces costs by increasing productivity and equipment service life. For additional information, visit www.pmiind.com.

For undergraduates from the Cleveland area, the Emerging Scholars Program offers a path to excellence

In the spring of 2011, a few weeks after he had accepted an offer of admission to Case Western Reserve, Terrence Mathis (CWR ‘16) opened a letter from a faculty member he had never met.

Stephen Haynesworth (GRS ‘87), an associate dean in the College of Arts and Sciences, had written to congratulate Mathis and assure him that he had made the right decision. “When we at CWRU admitted you to the university,” Haynesworth told him, “we demonstrated our respect for your achievements and our confidence that you can succeed here.”

- 1

- 2