For decades, PMI has been extremely focused on building the best products that withstand the extreme environments of the deep ocean. But as we’ve come to work with Offshore Wind and Renewable Energy companies, we understand our product doesn’t have to be used in the deepest and harshest place on our planet, the sea. Instead, rivers in rural areas are a huge focus of the renewable energy field today. And these companies are offering solutions that serve a large portion of the population, who still have no access to electricity.

……………………………………………………………………………………………………………………

We see a great future in the power coursing through our rivers. And, of course, we will be providing cable equipment for these projects as they evolve. If you want to know more about our custom engineered cable hardware equipment, schedule to talk to our experts today.

……………………………………………………………………………………………………………………

India is facing an energy revolution. Despite broad grid coverage, electricity supply in remote areas remains unreliable. For the future, the government is setting a favorable political scenario by introducing solutions for decentralized electrification based on renewable energies, such as photovoltaic (PV), small wind, and explicitly kinetic hydropower.

Companies such as Smart Hydro Power have the advantage of realizing its systems in rural areas, without the requirement for any kind of infrastructure, suitable for running canals, rivers and streams, which inhabit a large portion of India’s typography. At the distribution part of this system, integrated load management introduces an auxiliary productive load – a water purification plant – that utilizes all excess energy and stabilizes the micro grid with variable operation. Through this feature, additional value is brought to the lifestyle of people residing in these communities. Read more…

The main ambition behind the development of the Smart Hydro Power turbine was cost efficiency. Selected materials had to be robust and yet affordable which resulted in a majority of HDPE, aluminum and stainless steel components. The turbine consists of a three bladed rotor, a 5 kW generator, the floating body consisting of a three piece diffusor and two floats.

Watch how it works here: http://www.smart-hydro.de/en/product/turbine.html

Drawing energy from river currents represents a massive untapped source of electricity development. This is especially true in countries like Canada, where rivers and coastal waters provide an enormous range of development options that can provide growth and economic benefits.

Indeed, Canada is emerging as a leader in the global marine renewable energy industry, thanks to supportive government policies, shared infrastructure and strategic research initiatives. These facts provided the backdrop for last week’s Marine Renewables Canada 2015 Annual Conference, where PMI was among the vendors showcasing products and services in the fast-growing renewables market.

At PMI, we’re already reaching out to companies in the offshore-wind sector, and we’re seeing the potential of freshwater rivers to provide clean, renewable energy.

River energy initiatives provide a new twist on age-old technology: the water wheel. New ventures in this sector are exploring placing turbines — much like you’d see on a jet aircraft — deep in the waters of a river. Water turns the blades, generating kinetic energy that can be converted into electricity.

This creates the potential to fix the one major drawback of hydroelectric projects: massive dams that devastate the local environment. Rivers also can provide power around the clock, unlike solar panels.

Canadian businesses and researchers are unlocking the potential of marine renewable energy through innovations and new approaches to key challenges in the lifecycle of wave, tidal and river projects. Solving problems here definitely opens opportunities in the global market.

PMI is proud to be on the cutting edge of this opportunity, supplying contractors with our proven subsea hardware equipment for river energy exploration. At Marine Renewables Canada 2015, we gobbled up knowledge on topics including:

- Technical acceptability — an international effort to reduce technical risk

- Building scale — an international project pipeline

- Supplying the industry — device development

We see a great future in the power coursing through our rivers. And, of course, we will be providing cable equipment for these projects as they evolve. If you want to know more about our custom engineered cable hardware equipment, schedule to talk to our experts today.

Offshore wind might be a new industry, but they are as just as focused on cost efficiencies and simplified solutions as our clients in oil and gas. Those who support them need to supply and produce reliable products that increase performance and lower costs.

Our past customers pushed us to innovate and develop “No Tools Required” custom cable systems, and our in-depth hydrodynamic efficiency studies are helping other companies innovate new systems on existing subsea cable devices and analyze cost saving opportunities.

And we are not alone in our efforts. German industrial group Siemens unveiled a new direct-current solution for connecting offshore wind turbines to the grid which can lower costs by as much as 30%. Read more.

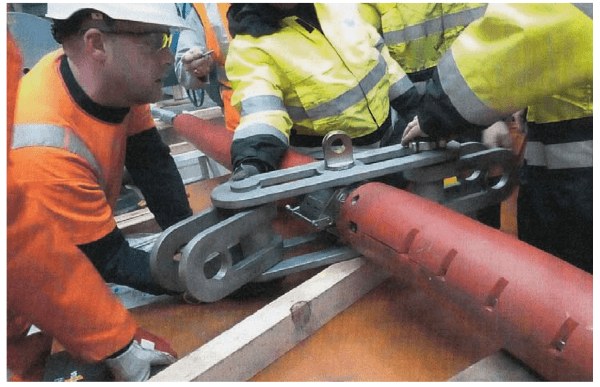

When laying and retrieving submarine cables on the seabed, or performing a cable pull from a vessel to an offshore wind platform, it is often necessary to hold a cable end onboard for up to seven days.

Cables must be anchored firmly onboard to keep them in place, and this anchoring is normally done by means of a cable stopper.

The cable left hanging in the ocean can be exposed to forces so strong there is a distinct possibility of becoming overtensioned. Meanwhile, the vessel’s crew works to keep station by the use of thrusters. If overwhelmed by winds, strong currents and waves, the ship can be driven out of position. The cable left hanging may end up acting as an anchor chain, subject to additional forces and tension.

In these situations, when the wrong cable hardware is used, or is installed incorrectly, the grip of cable tensioners can slip. The heavy cable starts moving unfastened, which is extremely dangerous for the crew, equipment and the vessel.

While the oil, gas and seismic industries have had plenty of experience with these issues, the growing offshore renewable energy companies are looking to manufacturers like PMI Industries for proven experience and products to guide the way.

Engineers who have made the leap from offshore oil to offshore renewable energy have worked with PMI’s products, such as our CABLE-GRIP™ and STOPPER-GRIP™ Terminations, and have found them preferable to typical braided cable grips or cable socks. These terminations are quick and easy to install, robust, and recommended by many cable deck crews.

Our unique cable grips are fully capable of holding cables to the rated breaking strength. Tensile load is transferred gradually from cable to termination with no stress or damage to the cable. And unlike braided stoppers, the helical termination wire design permits installation anywhere along the length of the subsea cable, since it does not require access to the cable end.

7 Questions You Should Be Asking About Your Subsea Terminations

You may not have noticed, but offshore wind is taking our world by storm.

Since offshore wind turbines are transported by ships and barges, they easily reduce logistical challenges that land-based turbines encounter, such as narrow roadways or tunnels. This allows offshore wind developers to build larger turbines capable of producing more electricity.

But what’s really exciting is that offshore wind turbines can float. Several U.S. companies are developing innovative floating offshore wind platforms for use in deep waters. These floating platforms are placed in water depths where bottom-mounted towers are not feasible. Their structures are tethered to the seabed with cables.

And where there are cables, there is cable hardware.

We’ve been creating subsea cable hardware for years. Today our products, which offer protection against cable bending and abrasion, are being adapted for the renewable energy field.

This need for subsea cable hardware will be on the rise right along with the demand of

clean, renewable energy to fulfill the electrical needs of cities along U.S. coastlines. And being located near the east coast, where many of the first offshore wind farms will be developed, means we are a close resource for the industry.

Read more about our thoughts on wind energy.

Here are all top 10 things you didn’t know about offshore wind energy.

Although we are located in the States, we assist companies world-wide with marine cable hardware, deployment, and management. Therefore, we’ve had a front row seat watching Europe position itself as a leader and pioneer in addressing climate change, creating jobs in the offshore wind sector, and reducing fossil fuel imports.

And while offshore wind is years behind onshore wind, the industry is displaying one of the fastest growth rates in the industry. The pace of growth, however, needs to be matched by an equal pace in reducing costs. Success will depend not only on how much it can reduce costs, but also how fast it can reduce costs.

As the U.S. starts installing the foundations for their first offshore wind farm, they will have these same issues to contend with as well as the struggling opposition found along our coast.

Read more about offshore wind here.

Read more about North America’s first offshore wind farm:

Rhode Island’s Deepwater Wind will start installing the foundations for North America’s first offshore wind farm on Monday, a milestone the company says could pave the way for an industry long established in Europe but that is still struggling with opposition in the United States.

PMI has grown up with the oil industry. In 1969, we emerged in the underwater market by introducing the helical wire concept for use on underwater cables. And today, we offer full-service engineering from concept to production, cable hardware and kits, custom cable systems and simulated at-sea testing services.

The recent trend in oil prices casts a shadow of uncertainty on many industries like ours across the globe. But news of a Norwegian oil field has us all perking up a bit.

The Ministry of Petroleum and Energy has given the go ahead on the development and operation plan of the oil group Statoil for Johan Sverdrup field. It’s the fifth largest oil field to ever be found off the Norwegian cost. And it looks as if it is expected to generate $200 billion in revenues within the next 50 years and create 51,000 direct and indirect jobs, which is especially important for Norway – not to mention the entire oil industry — these days.

Read more about our thoughts on Oil and Gas Exploration.

Read more about Norway’s Development of Largest Oil Field.

There’s no shortage of bad news these days, but looking at the trends in renewable energy, there’s plenty of hope. Last year, the world broke a record for new wind installations, installing nearly three wind turbines each hour. At that rate the need for proven subsea equipment will certainly increase as well. At PMI, we are focused on this market, the trends that will lead the energy revolution and helping these customers realize a significant return on investment.

Wind energy is surging back to stronger levels of investment is just one of the trends. Read about all them here.

As we find our products being used more and more for shipwreck explorations, we were really excited to read about this one nearly in our backyard in Lake Michigan and learning that there are many more to discover.

The bottom of Lake Michigan is literally a graveyard of shipwrecks. Local maritime historians say 1,200 of the 2,000 sunken vessels in Lake Michigan no longer exist because they hit shore and broke apart.

Experts add that about 360 wrecks have been found in the lake’s deeper water, but there are still many wrecks out there that remain undiscovered. Read more…

Subsea equipment (umbilicals, risers, flowlines) and pipelines are generally one third of all expenditure of a total project. Equipment purchases add up quickly and in order to save costs, companies will be looking for hardware with proven results – hardware that increases efficiency and quickly realizes a significant return on investment.

Statoil CEO Eldar Sætre recently stated that over the last ten years, the cost of subsea developments has increased by 250 percent. According to analysts Douglas-Westwood, subsea spending will continue to rise, and there are projects and locations to watch out for. Read more…

- 1

- 2