Offshore wind and solar energy have been getting all the attention in the quickly growing renewable energy industry, but there’s another player that is beginning to grow strength in the energy market – ocean waves and tidal currents, or “marine energy”. There are vast amounts of energy that are produced within the moving waters of oceans and rivers, and companies working to harness this energy are quickly gaining speed.

While not nearly as large as the main competitors in renewables, marine energy has strong advocates and is quickly gaining steam in the renewable market. About 30 tidal and 45 wave energy companies are at an advanced stage of technological development. One of the biggest issues these companies are facing that has impeded forward movement in the market is the harsh ocean environments – the same thing that makes the industry work in the first place.

The intensity of sea waves is greatly unpredictable and can cause damage throughout the process. Installation of the equipment is often difficult – the areas that are best suited to harness wave and tidal energy are often very hazardous and can be difficult to navigate. As we mentioned in our article on subsea cable vulnerability, subsea cables and hardware have to withstand 14.5 psi per every 10.05 meters they are lowered into the ocean. That coupled with the harsh environment that marine energy succeeds in, makes for a harsh environment for equipment.

PMI has many years of experience engineering proven subsea hardware for companies around the globe. We are excited to be part of the quickly growing marine energy market and are ready to create custom and quality solutions that will withstand harsh and hazardous environments.

Read more about the potential of wave and tidal energy.

The outcome of your project will rely on the quality of your subsea terminations. Make sure to download our guide – 7 Questions You Should Be Asking About Your Subsea Terminations – for a through breakdown of what you should be looking for in your subsea terminations.

As the energy market continues to turn away from oil and gas and towards renewable energy, many companies that specialize in deep ocean engineering, like PMI, are following suit. One company that has made great efforts to shift from oil and gas into the renewable energy field are the Norwegian subsea specialists Ocean Installer. The company’s advanced vessel, the Normand Vision, was used for work on subsea umbilicals, risers and flowlines (SURF) for major companies in the oil industry. Realizing that their subsea construction support equipment could also be used to work on the underwater cables that connect offshore wind platforms with the power grid, the Normand Vision began working with wind farms, including Germany’s Gode Wind 1 farm. Ocean Installer is not the only subsea construction company to jump on the renewable energy bandwagon. Singapore’s EMAS has also begun adding wind energy projects to their portfolio.

PMI shares the vision of these companies as our energy markets focus on new horizons and is excited to work with customers to solve their cable issues with budget friendly and top quality underwater cable hardware that will maintain cable integrity in every kind of underwater environment.

Read more about Ocean Installer and the Normand Vision.

To find out more about our custom ocean engineered cable hardware equipment, schedule an appointment to talk to our experts today.

For decades, PMI has been extremely focused on building the best products that withstand the extreme environments of the deep ocean. But as we’ve come to work with Offshore Wind and Renewable Energy companies, we understand our product doesn’t have to be used in the deepest and harshest place on our planet, the sea. Instead, rivers in rural areas are a huge focus of the renewable energy field today. And these companies are offering solutions that serve a large portion of the population, who still have no access to electricity.

……………………………………………………………………………………………………………………

We see a great future in the power coursing through our rivers. And, of course, we will be providing cable equipment for these projects as they evolve. If you want to know more about our custom engineered cable hardware equipment, schedule to talk to our experts today.

……………………………………………………………………………………………………………………

India is facing an energy revolution. Despite broad grid coverage, electricity supply in remote areas remains unreliable. For the future, the government is setting a favorable political scenario by introducing solutions for decentralized electrification based on renewable energies, such as photovoltaic (PV), small wind, and explicitly kinetic hydropower.

Companies such as Smart Hydro Power have the advantage of realizing its systems in rural areas, without the requirement for any kind of infrastructure, suitable for running canals, rivers and streams, which inhabit a large portion of India’s typography. At the distribution part of this system, integrated load management introduces an auxiliary productive load – a water purification plant – that utilizes all excess energy and stabilizes the micro grid with variable operation. Through this feature, additional value is brought to the lifestyle of people residing in these communities. Read more…

The main ambition behind the development of the Smart Hydro Power turbine was cost efficiency. Selected materials had to be robust and yet affordable which resulted in a majority of HDPE, aluminum and stainless steel components. The turbine consists of a three bladed rotor, a 5 kW generator, the floating body consisting of a three piece diffusor and two floats.

Watch how it works here: http://www.smart-hydro.de/en/product/turbine.html

Drawing energy from river currents represents a massive untapped source of electricity development. This is especially true in countries like Canada, where rivers and coastal waters provide an enormous range of development options that can provide growth and economic benefits.

Indeed, Canada is emerging as a leader in the global marine renewable energy industry, thanks to supportive government policies, shared infrastructure and strategic research initiatives. These facts provided the backdrop for last week’s Marine Renewables Canada 2015 Annual Conference, where PMI was among the vendors showcasing products and services in the fast-growing renewables market.

At PMI, we’re already reaching out to companies in the offshore-wind sector, and we’re seeing the potential of freshwater rivers to provide clean, renewable energy.

River energy initiatives provide a new twist on age-old technology: the water wheel. New ventures in this sector are exploring placing turbines — much like you’d see on a jet aircraft — deep in the waters of a river. Water turns the blades, generating kinetic energy that can be converted into electricity.

This creates the potential to fix the one major drawback of hydroelectric projects: massive dams that devastate the local environment. Rivers also can provide power around the clock, unlike solar panels.

Canadian businesses and researchers are unlocking the potential of marine renewable energy through innovations and new approaches to key challenges in the lifecycle of wave, tidal and river projects. Solving problems here definitely opens opportunities in the global market.

PMI is proud to be on the cutting edge of this opportunity, supplying contractors with our proven subsea hardware equipment for river energy exploration. At Marine Renewables Canada 2015, we gobbled up knowledge on topics including:

- Technical acceptability — an international effort to reduce technical risk

- Building scale — an international project pipeline

- Supplying the industry — device development

We see a great future in the power coursing through our rivers. And, of course, we will be providing cable equipment for these projects as they evolve. If you want to know more about our custom engineered cable hardware equipment, schedule to talk to our experts today.

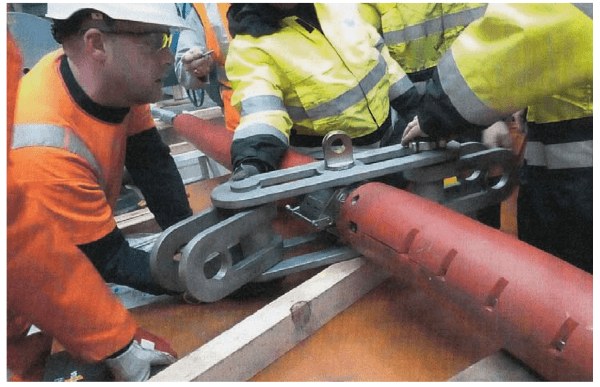

When laying and retrieving submarine cables on the seabed, or performing a cable pull from a vessel to an offshore wind platform, it is often necessary to hold a cable end onboard for up to seven days.

Cables must be anchored firmly onboard to keep them in place, and this anchoring is normally done by means of a cable stopper.

The cable left hanging in the ocean can be exposed to forces so strong there is a distinct possibility of becoming overtensioned. Meanwhile, the vessel’s crew works to keep station by the use of thrusters. If overwhelmed by winds, strong currents and waves, the ship can be driven out of position. The cable left hanging may end up acting as an anchor chain, subject to additional forces and tension.

In these situations, when the wrong cable hardware is used, or is installed incorrectly, the grip of cable tensioners can slip. The heavy cable starts moving unfastened, which is extremely dangerous for the crew, equipment and the vessel.

While the oil, gas and seismic industries have had plenty of experience with these issues, the growing offshore renewable energy companies are looking to manufacturers like PMI Industries for proven experience and products to guide the way.

Engineers who have made the leap from offshore oil to offshore renewable energy have worked with PMI’s products, such as our CABLE-GRIP™ and STOPPER-GRIP™ Terminations, and have found them preferable to typical braided cable grips or cable socks. These terminations are quick and easy to install, robust, and recommended by many cable deck crews.

Our unique cable grips are fully capable of holding cables to the rated breaking strength. Tensile load is transferred gradually from cable to termination with no stress or damage to the cable. And unlike braided stoppers, the helical termination wire design permits installation anywhere along the length of the subsea cable, since it does not require access to the cable end.

7 Questions You Should Be Asking About Your Subsea Terminations

As we find our products being used more and more for shipwreck explorations, we were really excited to read about this one nearly in our backyard in Lake Michigan and learning that there are many more to discover.

The bottom of Lake Michigan is literally a graveyard of shipwrecks. Local maritime historians say 1,200 of the 2,000 sunken vessels in Lake Michigan no longer exist because they hit shore and broke apart.

Experts add that about 360 wrecks have been found in the lake’s deeper water, but there are still many wrecks out there that remain undiscovered. Read more…

Subsea equipment (umbilicals, risers, flowlines) and pipelines are generally one third of all expenditure of a total project. Equipment purchases add up quickly and in order to save costs, companies will be looking for hardware with proven results – hardware that increases efficiency and quickly realizes a significant return on investment.

Statoil CEO Eldar Sætre recently stated that over the last ten years, the cost of subsea developments has increased by 250 percent. According to analysts Douglas-Westwood, subsea spending will continue to rise, and there are projects and locations to watch out for. Read more…

If you are looking to lower costs and improve the economic outcomes of deepwater projects, you should consider the hydrodynamic efficiency of your subsea hardware and how that impacts your fuel costs.

It’s everyone’s favorite pastime, but no one can predict what the oil price might be—it’s an uncontrollable aspect that can and will again dramatically impact this business over time. But what can and is being implemented by most companies is the overriding imperative to take back control where it can, and that largely means reducing project costs. Read more…

At PMI, we offer mechanical testing of all subsea cable hardware, including umbilical components and umbilical structures. We possess the equipment and experience necessary to complete the most demanding testing in order to enhance project safety and quality.

Umbilical designs for deepwater are complicated and present a number of challenges that must be considered during early design stages. If not correctly taken into account, they can cause problems and limitations during installation and in service. The trend of incorporating more functional components into the design leads to heavier umbilicals and, coupled with greater water depths, results in much higher topside hang-off loads. This drives umbilical designers to further understand the behavior and limits of their products. Read more…

Companies and governments count on PMI engineering support to design and produce reliable cable systems. They look to PMI for innovation to increase performance, specifically for the brutal subsea environment. Because at PMI, we understand the subsea poses challenges unlike any other environment in the world.

Our equipment is highly-designed to guard against cable and equipment damage, extend service life, and maintain cable integrity in these extreme underwater environments.

As in the planning of any asset development, the decision-making process attempts to maximize asset value and to minimize costs without compromising safety and reliability. The cost analysis focuses on capital expenditures and operating expenses, and it also includes risks, or the potential costs of unforeseen events. The conditions driving these costs are numerous and interrelated, and they include reservoir-related factors including existing infrastructure, water depth, weather and currents, seabed conditions, cost of construction and decommissioning of permanent structures, time to first production, equipment reliability, well accessibility for future monitoring or intervention, and flow assurance – the ability to keep fluids flowing in the lines. Read more…