At PMI, we offer mechanical testing of all subsea cable hardware, including umbilical components and umbilical structures. We possess the equipment and experience necessary to complete the most demanding testing in order to enhance project safety and quality.

Umbilical designs for deepwater are complicated and present a number of challenges that must be considered during early design stages. If not correctly taken into account, they can cause problems and limitations during installation and in service. The trend of incorporating more functional components into the design leads to heavier umbilicals and, coupled with greater water depths, results in much higher topside hang-off loads. This drives umbilical designers to further understand the behavior and limits of their products. Read more…

Companies and governments count on PMI engineering support to design and produce reliable cable systems. They look to PMI for innovation to increase performance, specifically for the brutal subsea environment. Because at PMI, we understand the subsea poses challenges unlike any other environment in the world.

Our equipment is highly-designed to guard against cable and equipment damage, extend service life, and maintain cable integrity in these extreme underwater environments.

As in the planning of any asset development, the decision-making process attempts to maximize asset value and to minimize costs without compromising safety and reliability. The cost analysis focuses on capital expenditures and operating expenses, and it also includes risks, or the potential costs of unforeseen events. The conditions driving these costs are numerous and interrelated, and they include reservoir-related factors including existing infrastructure, water depth, weather and currents, seabed conditions, cost of construction and decommissioning of permanent structures, time to first production, equipment reliability, well accessibility for future monitoring or intervention, and flow assurance – the ability to keep fluids flowing in the lines. Read more…

Forward-thinking and progressive companies will push sustainable energy technology and innovation further, testing its boundaries. These companies will advance as they see the value in environmental advocacy. They will be very focused on time and cost cutting methods. At PMI, we are looking into the future with these companies, helping reduce their costs through the use of hydrodynamic efficient hardware. Our in-depth hydrodynamic efficiency studies can be done on existing subsea devices for a complete cost analysis, as well.

In the world of energy, time and money are of the essence. Whether it be meeting projects completions, cost recovery or investor returns, entering the sustainable energy market has very real risks. All variables in the energy sector are related to time and cost. This is even truer in the sustainable energy sector. In order to get off the ground floor, in order to thrive, new emerging technologies and companies in this sector will require the removal of barriers to entry, which at times contain the much maligned red-tape. Read more…

Tidal energy farms require cables. And we understand that the lifetime of those cables significantly effect O&M costs. That’s why as the demand for tidal energy grows, we expect to find ourselves a long-time supplier in this market. Our product are designed to guard against cable and equipment damage, extend service life and maintain cable integrity in extreme underwater environments. Our hardware is proven to reduce the cost of maintaining subsea cables over time.

How the world is harnessing the power of the tides:

The Bay of Fundy is receiving a great deal of attention from proponents of ocean energy and from those in the industry seeking a more sustainable and green future. This 270 km long ocean bay is located in Atlantic Canada between the provinces of Nova Scotia and New Brunswick. The Bay of Fundy is where you will witness the highest and most spectacular tides in the world with 100 billion tons of seawater flowing in and out daily during each tidal cycle. This enormous power is currently being harnessed to generate electricity via tidal in-stream energy conversion (TISEC). Numerous projects and research initiatives are underway. With growing demand all over the world for renewable, clean, and carbon-free energy generation, tidal energy is quickly becoming a top choice over traditional wind and solar power. Read more…

One way PMI Industries is able to help companies accelerate and streamline subsea projects is by designing and testing cable hardware solutions upfront. In our Independent Test Lab, your engineers simulate service conditions experienced by underwater cable systems and devices. Once testing is completed, the implementation cycle is accelerated, ensuring projects like RiCORE run smoothly.

The RiCORE (Risk Based Consenting for Offshore Renewable Energy) project has been awarded €1.4 million from the European Commission’s competitive Horizon 2020 programme.

Led by Robert Gordon University (RGU), a group comprising teams from Ireland, Spain, Portugal, France and Scotland will look at ways of accelerating and streamlining the environmental requirements associated with consents for offshore wind, wave and tidal projects. Read more…

As wind power grows in the UK, it is certain to grow in the US. PMI’s experience designing and producing reliable cable systems for offshore wind projects will benefit companies looking to innovate, increase performance and lower costs.

The UK Department of Energy and Climate Change has released results of a public attitude tracking survey, which shows support for offshore wind power has remained stable since the last survey.

According to DECC’s findings, support for individual renewable energy sources remain positive; offshore wind (74%), onshore wind (68%), wave and tidal (74%) and solar (81%). Read more…

Prior to the show, Gordon Drummond was quoted, saying: “In the current low oil price environment, innovation and technology will be more important than ever in driving efficiencies and developing effective solutions to the challenges the industry presently faces, particularly in the North Sea.”

Driving technology in subsea cable applications is what we do. Our cable hardware solutions deliver efficiencies and provide exceptional return on investment.

New technologies, and how their implementation can boost oil and gas exploration, was brought to the forefront at this year’s Subsea Expo.

For the first time, Subsea UK’s annual conference and exhibition, which took place from February 11-13, provided a platform for organizations to introduce, discuss and demonstrate their latest innovations. Read more…

Scientists and researchers are tackling HABs in Lake Erie, which have depleted the oxygen from the deeper waters off Cleveland. PMI specializes in producing some of the heavy-duty equipment being deployed in order to solve this problem.

The season of algal blooms — the green slime that coats the water — and dead zones is upon Lake Erie. This year, though, joining the fight is the Lake Guardian, the U.S. EPA’s 180-foot, 850-ton environmental battleship, loaded with scientists and researchers.

The Lake Guardian is on the water at a crucial time: The push is on in Washington, D.C., and Columbus to add millions of dollars to the anti-algae effort, sewage treatment plant upgrades are being put in place and there are indications that this summer’s algal bloom may be less severe than recent years.

“This is an intensive year for Lake Erie,” said Chief Paul J. Horvatin of the U.S. EPA’s Great Lakes National Program Office in Chicago. “We’ve been here to look at nutrient and phosphorus issues since mid-May and we’ll continue our research into the middle of October.”

With an 11-man crew and 13 scientists aboard, and more local researchers joining them this summer on Lake Erie, the R/V Lake Guardian is extensively sampling the Ohio waters of Lake Erie from Toledo to Conneaut. Read more…

The launch of the Ramform Titan class marine seismic data acquisition ships by Petroleum Geo-Services (PGS) mark a new era of subsea oil and gas exploration. The second of these vessels, the Ramform Atlas was launched in January, 2014. The Ramform Titan and Ramform Atlas are designed and built by PGS to be the most powerful and productive of their kind using the latest marine and electronic seismic technologies.

Every detail of these vessels was evaluated based on optimum productivity and safety including the cable management systems used to deploy and attach up to a 24-streamer array system. The towed streamers consist of several thousand recording sensors over an area greater than 3,000 acres (12 km2), or 3.5 times the size of New York’s Central Park.

The engineers at PGS have chosen the latest proven technologies available throughout the Ramform Titan-class ships, including the new PMI Dyna-Hanger II and Dyna-BSR cable management systems. These systems provide significantly higher load capacities to accommodate the demands of extreme towing loads caused by wider streamer arrays. As a bonus, the major components of both systems can be installed, or removed, in just minutes without special tools or extensive personnel training to increase on deck productivity and reduce downtime.

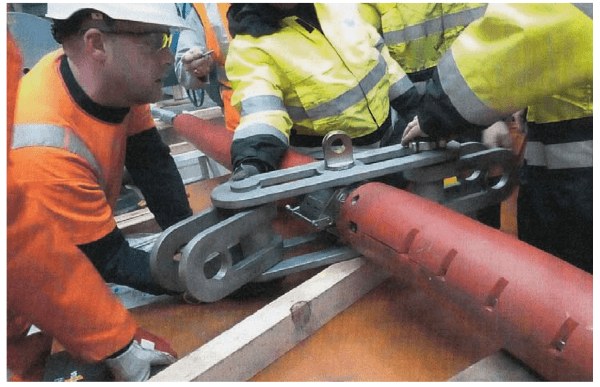

The Dyna-Hanger II cable management system uses exclusive patent pending designed symmetrical suspension arms with tool-less features and helical rods. It is designed with a hinged collar that snaps around the housing and is secured with just a quick-release pin. A specially designed housing prevents the attachment point from shifting on the lead-in cable while the collar design enables the cable to rotate freely under tension. It is capable of accommodating loads up to 100% of the cable’s rated breaking strength.

The Dyna-BSR bending strain relief system provides cable bending and abrasion protection, while enabling rotation of various cable attachments. It replaces traditional slip-on bending strain relief systems that use a one-piece body design. Instead, the Dyna-BSR patent pending two-piece system can be installed or removed at any time during deployment or retrieval procedures. It is designed with a reinforced polyurethane, two-part shell to provide added strength and flexibility. A unique fastener system quickly secures the shells together. In total, the system offers graduated stiffness to protect cables from off-axis loads through a wide range of angle combinations by maintaining a safe minimum bend radius.

“Everything on the Ramform Titan class was chosen for its contribution to our primary goals of providing optimal seismic productivity and crew safety,” according to Sverre Olsen, Technical Manager at PGS. “Every sub-system we have, builds on the total system to achieve our goals. PMI systems were chosen because they continue to meet PGS productivity and higher load requirements.”

“The successful PGS installation is a result of our conversations with customers about their challenges then developing cable hardware and support services to meet their needs,” said Bob Schauer, president, PMI industries. “We are focused on unmatched support for our customers. Whether it is easy-to-use hardware, engineering support or comprehensive cable testing services, we listen and then perform.

The launch of the Ramform Titan class marine seismic data acquisition ships by Petroleum Geo-Services (PGS) mark a new era of subsea oil and gas exploration. The second of these vessels, the Ramform Atlas was launched in January, 2014. The Ramform Titan and Ramform Atlas are designed and built by PGS to be the most powerful and productive of their kind using the latest marine and electronic seismic technologies.

Every detail of these vessels was evaluated based on optimum productivity and safety including the cable management systems used to deploy and attach up to a 24-streamer array system. The towed streamers consist of several thousand recording sensors over an area greater than 3,000 acres (12 km2), or 3.5 times the size of New York’s Central Park.

The engineers at PGS have chosen the latest proven technologies available throughout the Ramform Titan-class ships, including the new PMI Dyna-Hanger II and Dyna-BSR cable management systems. These systems provide significantly higher load capacities to accommodate the demands of extreme towing loads caused by wider streamer arrays. As a bonus, the major components of both systems can be installed, or removed, in just minutes without special tools or extensive personnel training to increase on deck productivity and reduce downtime.

The Dyna-Hanger II cable management system uses exclusive patent pending designed symmetrical suspension arms with tool-less features and helical rods. It is designed with a hinged collar that snaps around the housing and is secured with just a quick-release pin. A specially designed housing prevents the attachment point from shifting on the lead-in cable while the collar design enables the cable to rotate freely under tension. It is capable of accommodating loads up to 100% of the cable’s rated breaking strength.

The Dyna-BSR bending strain relief system provides cable bending and abrasion protection, while enabling rotation of various cable attachments. It replaces traditional slip-on bending strain relief systems that use a one-piece body design. Instead, the Dyna-BSR patent pending two-piece system can be installed or removed at any time during deployment or retrieval procedures. It is designed with a reinforced polyurethane, two-part shell to provide added strength and flexibility. A unique fastener system quickly secures the shells together. In total, the system offers graduated stiffness to protect cables from off-axis loads through a wide range of angle combinations by maintaining a safe minimum bend radius.

“Everything on the Ramform Titan class was chosen for its contribution to our primary goals of providing optimal seismic productivity and crew safety,” according to Sverre Olsen, Technical Manager at PGS. “Every sub-system we have, builds on the total system to achieve our goals. PMI systems were chosen because they continue to meet PGS productivity and higher load requirements.”

“The successful PGS installation is a result of our conversations with customers about their challenges then developing cable hardware and support services to meet their needs,” said Bob Schauer, president, PMI industries. “We are focused on unmatched support for our customers. Whether it is easy-to-use hardware, engineering support or comprehensive cable testing services, we listen and then perform.”

The new Ramform Titan and Ramform Atlas put PGS further ahead as the leader in safe, productive and efficient 3D seismic acquisition.

About PGS

Petroleum Geo-Services (PGS) offers a broad range of products including seismic and electromagnetic services, data acquisition, processing, reservoir analysis/interpretation and multi-client library data. We help oil companies find oil and gas reserves offshore worldwide.

PGS was founded in Norway in 1991, with 2 seismic ships and some highly innovative ideas on how to reshape the industry. Today we share the same drive to innovate as inspired our founders, though the team is bigger:

- 14 offshore seismic vessels

- 21 data processing centers

- 35 offices worldwide, employing over 70 nationalities

PGS has a presence in over 25 countries with regional centers in London, Houston and Singapore. Our headquarters is in Oslo, Norway and the PGS share is listed on the Oslo stock exchange (OSE:PGS).

For more information, visit: www.pgs.com

About PMI Industries, Inc.

PMI Industries, Inc. provides underwater cable hardware products and services to customers worldwide including exploration, military, commercial and scientific organizations. The company supports domestic and international customers with comprehensive subsea knowledge, application assistance, custom designs and functional testing to assure performance and reliability in harsh operational environments.

The company was founded to solve cable and wire rope application problems. It introduced unique wire helix design to grip a conductor that provides the strength needed for assured cable connections while ensuring cable integrity.

For more information, visit: www.pmiind.com